A well-maintained machine suggests a history of diligent care, which is a significant factor for buyers looking for reliability in their manufacturing operations.

Prepare Your CNC Machine Shop for Sale: Essential Steps

Preparing Your California CNC Manufacturing Business For Sale

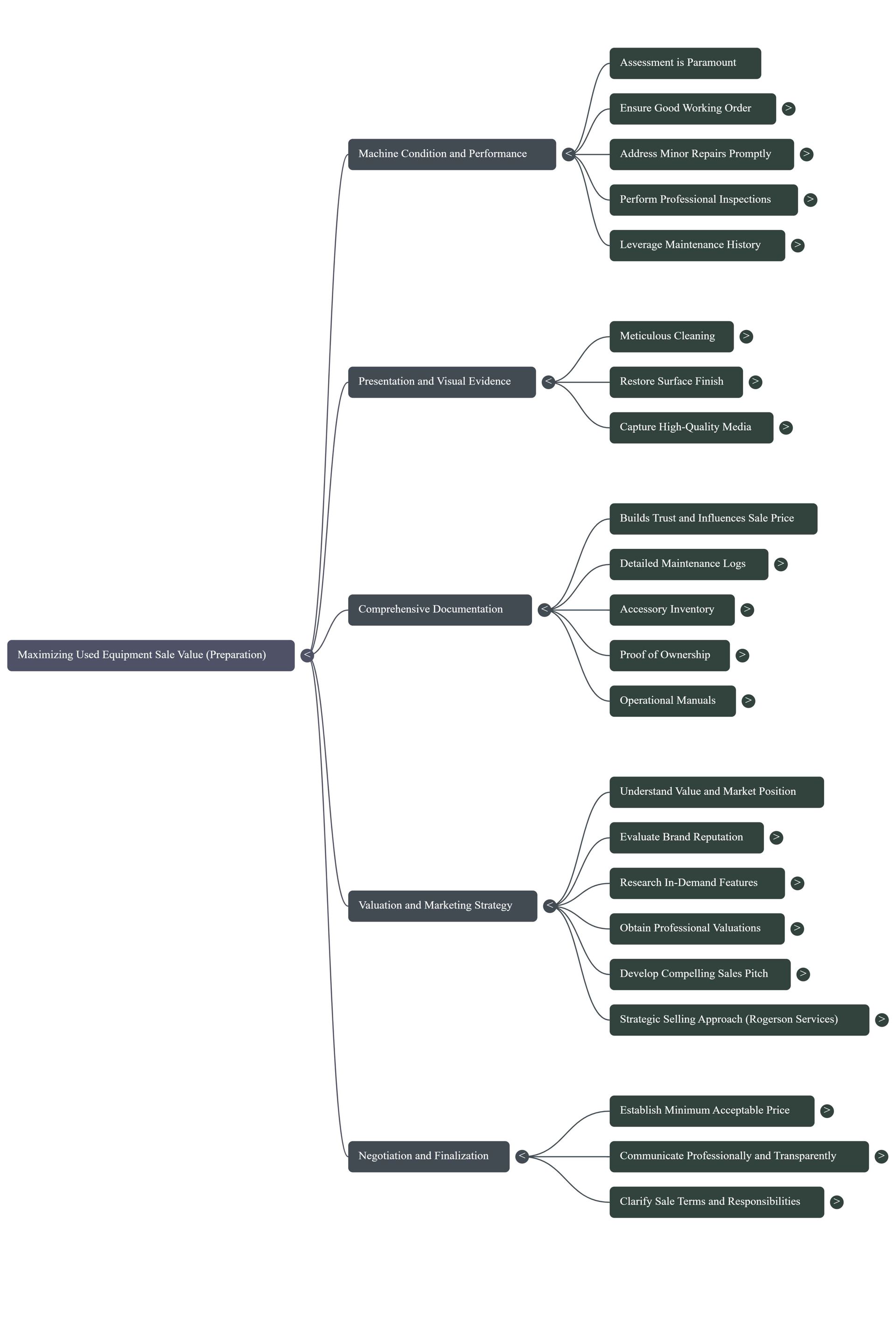

Preparing your CNC manufacturing business for sale? Learn essential steps: machine condition, cleaning, documentation, valuation, marketing, and negotiation for a successful sale.

Getting ready to

sell your CNC manufacturing business takes some thought. It's not just about putting a sign up and waiting for offers. You have to get things in order so potential buyers see the value. This guide walks you through the main steps to make the process smoother and get a better outcome when

preparing your California CNC manufacturing business for sale.

Key Takeaways

- Make sure your machines are in good working order and look their best. A clean, well-maintained machine is more attractive to buyers.

- Gather all paperwork related to your machines, including purchase records, maintenance logs, and manuals. Good documentation shows you've taken care of things.

- Understand what your machines are worth in the current market. Look at similar machines for sale and consider getting professional opinions.

- Figure out the best ways to advertise your business. This could involve online listings, working with dealers, or other selling methods.

- Be ready to talk price and terms with buyers. Know your lowest acceptable price and communicate clearly throughout the negotiation.

Table of Contents

Assess And Enhance Machine Condition

Before listing your CNC machine manufacturing business for sale in the competitive California market, a thorough assessment of your machines' condition is paramount. This step directly influences buyer perception and the ultimate sale price. Take the time to understand exactly what you are offering.

Determine Current Operational Status

First, evaluate how your machine is currently performing. Has it been running consistently, or has it been idle for an extended period? Note any unusual noises, vibrations, or performance dips. For idle machines, a test run is necessary to confirm that all axes and spindles operate as expected. This initial check provides a baseline for all subsequent evaluations and repairs.

Perform Professional Inspections

Consider bringing in a certified technician for a professional inspection. They can identify potential issues that might not be obvious to the untrained eye. A detailed inspection report from a reputable source acts as a strong selling point, offering buyers confidence in the machine's condition. This is particularly important for specialized equipment common in California's aerospace and manufacturing sectors.

Address Minor Repairs For Optimal Performance

Once you have a clear picture of the machine's state, address any minor issues. Small problems, like a loose fitting, a worn-out sensor, or a faulty indicator light, can deter buyers. Fixing these promptly not only improves the machine's overall performance but also signals to potential buyers that the equipment has been well-maintained. A machine that runs smoothly and looks cared for will command a higher price.

- Check all fluid levels and top off as needed.

- Inspect belts and hoses for wear and tear.

- Verify all safety guards are in place and functional.

Meticulous Cleaning And Presentation

Execute Thorough Exterior And Interior Cleaning

First impressions matter, especially in the competitive California CNC market. A clean machine signals good maintenance and care. Start by thoroughly degreasing the entire exterior, paying attention to all surfaces, panels, and even the back. Use an industrial-strength degreaser to cut through any built-up grime. Next, tackle the interior.

Remove any chips, coolant residue, or debris from the work area, spindle housing, and chip conveyors. A clean interior shows potential buyers that the machine has been operated responsibly. Don't forget to remove any old labels or tape residue; products like Goo Gone work well for this.

Restore Surface Finish With Polishing Compounds

After cleaning, the machine's exterior might still show signs of wear. To improve its appearance, use a quality polishing compound. Apply it to the painted surfaces to minimize the visibility of minor scratches and scuffs.

This step can make a significant difference in how well the machine presents itself. Follow up by buffing all metal surfaces with a metal polishing cream.

This brings back a shine and makes the machine look more recently maintained. A well-polished machine suggests a higher level of care and can justify a better selling price.

Capture High-Quality Photographs And Videos

Once the machine is spotless and polished, it's time to document its condition. Take well-lit, high-resolution photographs from multiple angles. Capture close-ups of key components like the control panel, spindle, and tooling areas. Additionally, shoot a video demonstrating the machine in operation. Show the spindles running, axes moving smoothly, and the control interface functioning.

A running video is particularly important for buyers in California who want to see the machine's performance firsthand. Ensure the video highlights that the machine operates without unusual noises. This visual evidence builds buyer confidence and can significantly speed up the sales process.

Don't have time to read more?

Take a shortcut and play the video overview below

Compile Comprehensive Machine Documentation

Gathering all relevant paperwork for your CNC machines is a vital step, especially when selling your business in the competitive California manufacturing market. Buyers want to see proof of ownership, maintenance history, and operational details. This documentation builds trust and can significantly influence the final sale price.

Gather Original Purchase and Ownership Records

Start by locating the original purchase invoice for each machine. This document confirms your ownership and provides the initial cost, which can be a reference point for valuation. Also, collect any title or registration documents if applicable. Having these records readily available simplifies the ownership transfer process.

Maintain Detailed Maintenance and Repair Logs

Buyers in the CNC sector, particularly in California's advanced manufacturing hubs, look for machines that have been well cared for. Keep meticulous records of all scheduled maintenance, part replacements, and any repairs performed. This history demonstrates a commitment to upkeep and can reassure potential buyers about the machine's reliability.

A clear log can look something like this:

| Date | Service Performed | Parts Replaced | Technician/Company | Notes |

|---|---|---|---|---|

| 2023-01-15 | Preventative Maintenance | Filter Set | In House | All systems checked, lubrication done |

| 2023-07-22 | Spindle Bearing Repair | Bearing P/N 123 | Certified Tech A | Noise reduction achieved |

| 2024-03-10 | Software Update | N/A | Vendor B | Latest firmware installed |

Include Operational Manuals and Accessory Inventories

Make sure you have the original operational manuals for each CNC machine. These guides are indispensable for new owners. Additionally, create a detailed inventory of all included accessories, tooling, fixtures, and any special software.

Clearly listing these items can add perceived value and attract a wider range of buyers.

For instance, if you have specialized tooling for aerospace components, highlight this in your inventory, as it could be a major draw for specific buyers in Southern California.

Understand Machine Value And Market Positioning

Evaluate Age, Usage, And Brand Reputation

When you think about how to sell a machine shop business in California, understanding what makes your equipment valuable is key. The age of your CNC machines and their usage hours directly impact their worth. Older machines with high operating hours generally command lower prices.

However, a strong maintenance history can significantly offset age. Reputable brands in the California market, like DMG Mori or Okuma, often retain more value due to their known durability and performance. Buyers look for reliability, so highlighting a well-maintained machine from a trusted manufacturer improves its market position.

Research Market Demand For Specific Features

Market demand plays a big role in how to sell your machine shop manufacturing company that you have been operating for many years, and now it is time to move on for the best price. Consider what features are currently sought after in the California manufacturing sector.

For instance, multi-axis capabilities (like 5-axis) are often in high demand for complex jobs. Also, machines with Industry 4.0 compatibility or IoT sensor integration are increasingly attractive. Identifying these in-demand features helps you position your equipment effectively and can boost your CNC manufacturing business valuation.

Obtain Professional Valuations And Dealer Consultations

To

get an accurate CNC machine shop valuation, professional input is invaluable. Comparing your CNC machines to similar listings on platforms like

MachineStation offers a starting point. However, consulting with experienced machinery dealers or brokers provides deeper insights. They understand the current market dynamics and can offer realistic price expectations. This step is critical for maximizing CNC business value and understanding your true market position before you list your assets.

You don’t need to dismantle your CNC machine shop business and sell off its components.

Rogerson Business Services, under the guidance of

seasoned M&A advisor Andrew Rogerson, can present your entire business to the market and sell it as a valuable asset. This approach is more advantageous for business owners operating in California.

Strategic Marketing And Sales Channels

Identify Optimal Selling Platforms

When planning your exit strategy for manufacturing, selecting the right places to list your CNC manufacturing business is key. For the California market, consider platforms that reach a broad audience of manufacturers. Online marketplaces specializing in industrial equipment are a good starting point. These sites often attract serious buyers actively looking for specific CNC machinery businesses for sale.

Additionally, industry-specific forums and trade association websites can be effective. Think about where potential buyers in aerospace, automotive, or medical device manufacturing in California are likely to search for equipment. A multi-channel approach often yields the best results.

Keep in mind, selling your CNC manufacturing business confidentially is a whole different ball game. This is what business owners in California we see choose over an open ad. Confidentiality is key to attracting key buyers without losing your employees and customers.

Andrew Rogerson has a steady business sale record of manufacturing businesses, which you can investigate how it was done.

See these case studies:

1.. Manufacturing business sold despite some choppy waters.

2. Bay Area manufacturing business sold for $36 million

3. Bay Area sink manufacturer sold for $1.55 million

See more case studies

Engage Professional Machinery Dealers

Working with a professional machinery appraisal can significantly streamline the selling a business process. These manufacturing business brokers have established networks of potential buyers and understand the nuances of the CNC manufacturing market, especially within California.

They can help price your business accurately and manage the marketing efforts. Many M&A advisors focus on specific types of manufacturing businesses, so finding one with experience in CNC machines and business will be most beneficial.

They often handle the complexities of the transaction, allowing you to focus on your business operations. Consider consulting with an M&A advisor like Andrew Rogerson, who has a strong track record in the local California manufacturing sector.

Develop A Compelling Sales Pitch

Crafting a strong sales pitch involves highlighting the unique advantages of your CNC business. Focus on how they meet the specific needs of manufacturers in California. Detail their condition, any recent upgrades, and their operational history.

Quantify benefits like increased efficiency, precision, or cost savings. For example, you might state, "This machine has consistently delivered parts within +/- 0.001 inch tolerance, reducing scrap by 15%." Presenting clear, factual information builds buyer confidence. Remember, your goal is to demonstrate the immediate value and long-term return on investment your equipment and the manufacturing business offer.

Negotiate Terms And Finalize The Sale

Establish Your Minimum Acceptable Price

Before entering negotiations for your CNC business, determine your absolute lowest acceptable price. This figure acts as your safety net, preventing you from accepting an offer that undervalues your hard work and investment. Consider all costs associated with selling a CNC business, including potential broker fees and legal expenses.

Knowing your bottom line helps you negotiate with confidence and avoid emotional decisions. For instance, if you're selling a CNC business in the competitive California market, understanding local market values is key to setting a realistic minimum. This preparation is a vital part of the CNC business sale process.

Communicate Professionally And Transparently

Open and honest communication builds trust, which is essential for a smooth transaction. Address buyer questions promptly and provide accurate information about the machinery and business operations.

Transparency throughout the CNC business sale process can prevent misunderstandings and potential deal-breakers later on. Be prepared to discuss any concerns a buyer might have, whether it's about machine capabilities or operational history. Remember, building rapport with the buyer can lead to a more favorable outcome for everyone involved.

Clarify Sale Terms And Responsibilities

Clearly define all terms and conditions of the sale before finalizing the agreement. This includes payment schedules, the timeline for transferring ownership, ensure compliance with any state-specific regulations. A well-documented agreement, often outlined in a Letter of Intent (LOI) and later a purchase agreement, protects both parties. Consider these common points:

- Payment Terms: Specify deposit amounts, payment methods, and the schedule for final payment.

- Transition Period: Detail any training or handover period required from the seller.

- Post-Sale Support: Outline any agreed-upon support or warranty.

- Non-Compete Clause: Define the scope and duration of any restrictions on the seller's future business activities.

Clearly defining responsibilities minimizes disputes after the sale. It's wise to have legal counsel review all final documents to ensure your interests are protected during the sale of a CNC business transaction.

Once you've agreed on the main points and are ready to seal the deal, it's time to wrap things up. This stage involves making sure all the paperwork is in order and that both sides are happy with the final agreement. Don't miss out on getting the best outcome for your business sale. Learn more about how we can help you finalize your sale smoothly.

Wrapping Up Your Sale Preparation

So, you've gone through all the steps to get your CNC machine shop ready for sale. It might seem like a lot of work, but taking the time to clean things up, fix what's broken, and gather all your paperwork really makes a difference. Buyers want to see a well-cared-for business, and having all your records in order shows you're organized and serious. This preparation helps you get a better price and makes the whole selling process go more smoothly.

Good luck with your sale!

Frequently Asked Questions

Why should I clean my CNC machine business before selling it?

Cleaning your CNC machine makes it look well cared for and can help you get a better price for your business. A spotless machine suggests it was maintained properly, which buyers find very appealing. Think of it like washing a car before selling it – it just looks much better and more valuable.

What kind of documents should I gather for the sale?

You should collect all important papers related to the machine and your business. This includes the original bill of sale, records of all maintenance and repairs, and the user manual. Having these documents proves ownership and shows the machine has been looked after, which builds buyer confidence.

How do I figure out the right price for my machine?

To find the right price, look at how old the machine is, how much it's been used, and its brand name. Also, check what similar machines are selling for online or ask experts. Knowing the market helps you set a price that's fair and attractive to buyers.

Should I fix small problems before selling?

Yes, it's a good idea to fix any small issues that affect how the machine works. Even minor repairs can make the machine run better and show buyers that it's in good shape. This can lead to a higher selling price and make the machine more desirable.

Where is the best place to sell my CNC manufacturing business?

You have a few choices. You can list it on online marketplaces where many people will see it, or you could work with a professional advisor who handles the selling process for you. Each option has its pros and cons, so consider what works best for you.

What should I do to show potential buyers the machine is working well?

Take clear, high-quality photos and videos of the machine from different angles. It's especially helpful to show a video of the machine running smoothly, demonstrating that all its parts are working correctly. This gives buyers a real look at the machine's condition.

Hey there! Can we send you a gift?

We just wanted to say hi and thanks for stopping by our little corner of the web. :) we'd love to offer you a cup of coffee/tea, but, alas, this is the Internet.

However, we think you'll love our email newsletter about building value and properly position your company before transition/exit your business ownership.

As a special welcome gift for subscribing, you'll also get our helping and educational guides, tips, tutorials, etc.. for free.

It's filled with the best practices for retiring serial business owners like Dan Gilbert, Larry Ellison, Warren Buffett, and many more.

Just sign up for our emails below.